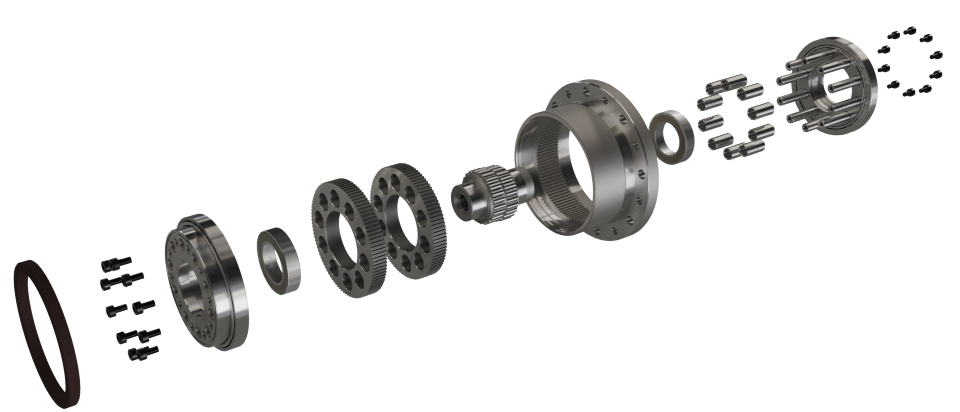

Structure / features

Structure / features

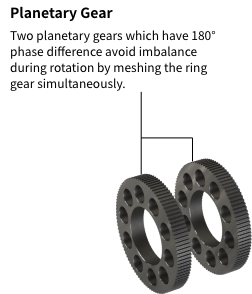

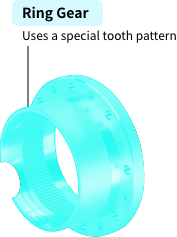

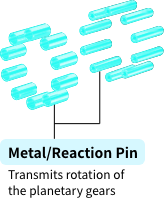

[Structure] High torque, a wide range of reduction ratios, and high stiffness for resistance to impacts.

[Features] A compact and flexible design is possible.

Achieves high precision positioning. High torque, a wide range of reduction ratios, and high stiffness for resistance to impacts.

A compact and flexible design is possible.

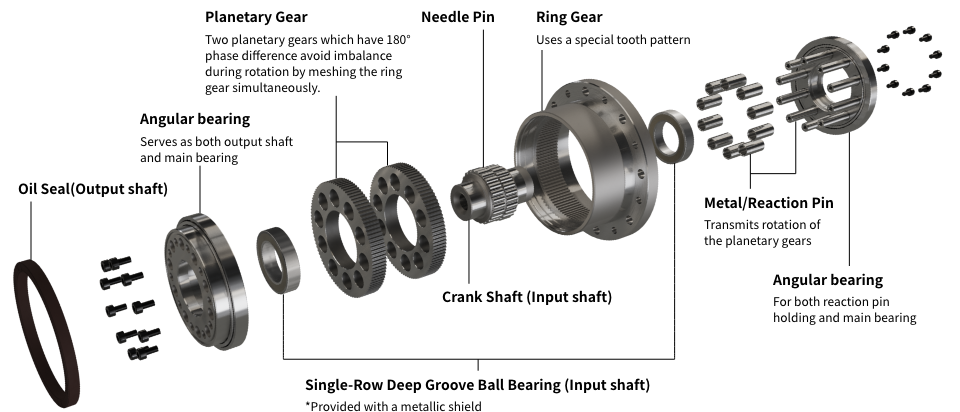

Release date: 2024.05.29 Click the image to watch the video.

The video is on YouTube.

Release date: 2024.08.29 Click the image to watch the video.

The video is on YouTube.

DGS type Precautions for Use

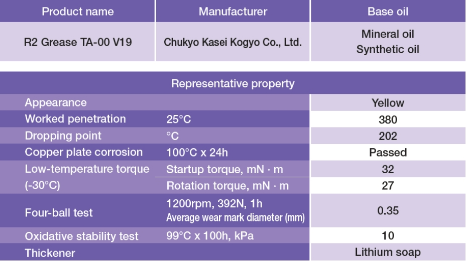

Lubrication/sealing material

Grease is sealed in the reducer when it is shipped from our factory.

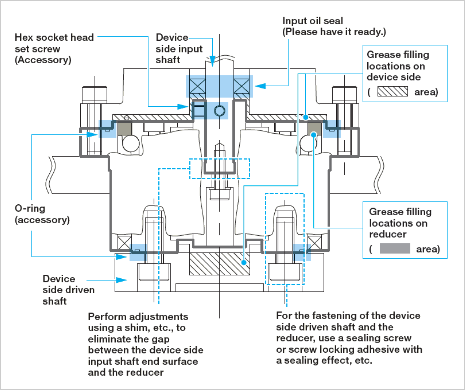

However, there is no oil seal installed on the device side input shaft.

If necessary, attach a seal to the device to prevent grease leakage.

[Important] On the device side, fill 70% to 80% of the spatial volume with our dedicated grease from the table below (sold separately).

For the DGS type, also fill the reducer with our dedicated grease (sold separately).

Refer to the installation example for the filling location.

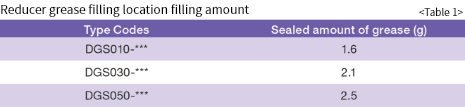

For the filling amount, refer to [Reducer grease filling location filling amount] in <Table 1>.

Precautions for the grease

1. Using grease in over or under designated amount or different grease may result in performance deterioration or early damage.

2. Be careful that no dirt or moisture, etc., gets inside. Failure to follow this precaution may result in failure.

The values shown above are representative values. Actual values may be slightly different depending on manufacturing lots.

Handling precautions

- Avoid direct sunlight, and store the reducer in a well-ventilated place.

- Please check the “Safety Data Sheet (SDS)” before starting to use.

[Example calculation of grease filling amount for grease filling locations on device side]

When the spatial volume of the device side is 24 cm3

Amount of grease filling on device side =

<Spatial volume> × <Grease density> × <Filling ratio>

=24cm3 × 0.9g/cm3 × 75%=16.2 g

Example of grease sealing space <Figure 1>

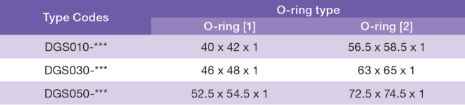

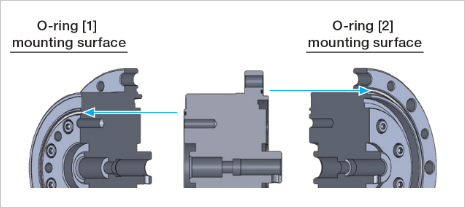

■ When installing this product, use the attached O-rings (two types).

Precautions for the O-rings

1. Before using O-rings, make sure that they are free from damage.

2. When mounting the O-rings, take care not to allow the adherence or entry of foreign substances and dust.

3. Be careful to avoid O-ring twisting and biting during the installation.

4. The O-ring contact surface of your device shall have a surface roughness of Ra 1.6 or less (Rz 3.2 or less).

Failure to follow this precaution may shorten the service life of the reducer due to grease leakage.

5. When installing the O-ring that is supplied as an accessory, the oil that has been applied may seep out, but this does not affect the quality.