HRH gear

HRH gear

What is the HRH gear

Introduction of NISSEI CORPORATION self developed technology HRH gear product.

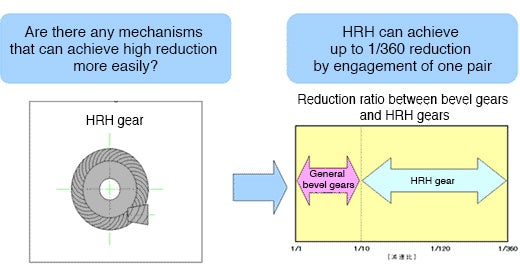

Difference between hypoid and High Ratio Hypoid Gear

| Hypoid | High Ratio Hypoid Gear | |

| Number of teeth | 5 or more | 1 or more |

| Tooth profile | Involute | Special surface |

Background of development

Performance of High Ratio Hypoid Gear - (1) Transmission efficiency

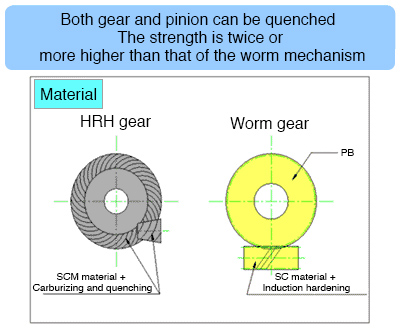

Performance of High Ratio Hypoid Gear - (2) Strength

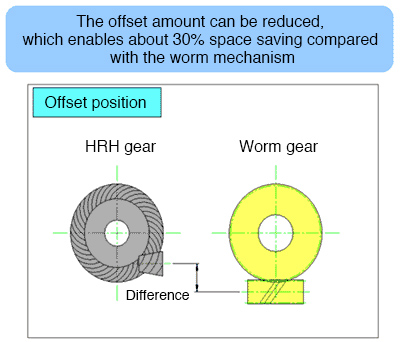

Performance of High Ratio Hypoid Gear - (3) Compact design

Performance of High Ratio Hypoid Gear - (4) Cost

Performance of High Ratio Hypoid Gear - (5) Example of use of an HRH gear (reducer for an automatic door)