High Precision Reducer

for Servo Motors

APG / AFC

Compact high precision reducer for servo motors

The high precision reducer APG type is compact and has high stiffness, thanks to the planetary mechanism, which contributes to downsize your device. In addition, the AFC type is made smaller thanks to the specially designed gear case. It has flexibility of installing at right angle which would save space for your Application .

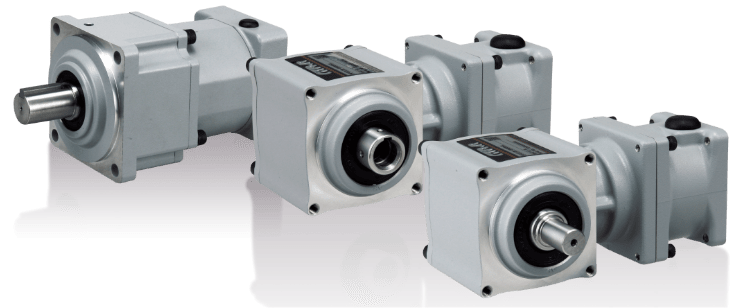

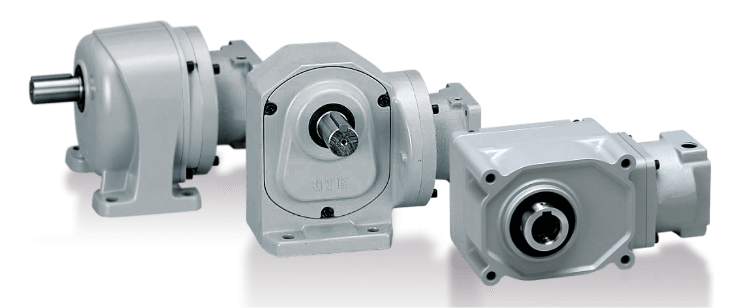

AG3 / AH2 / AF3

The gear head has the same shape as the induction gear motor

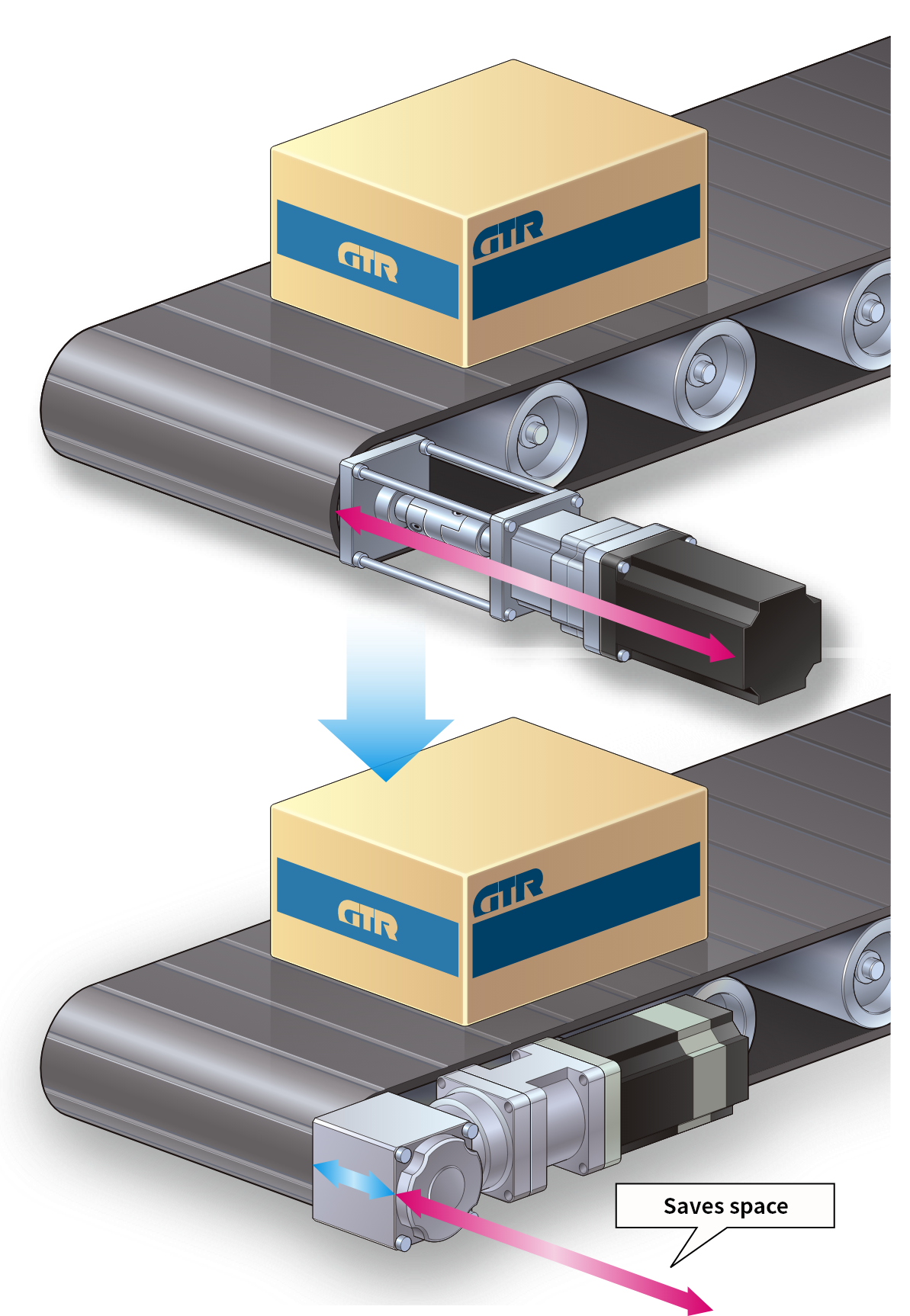

Features

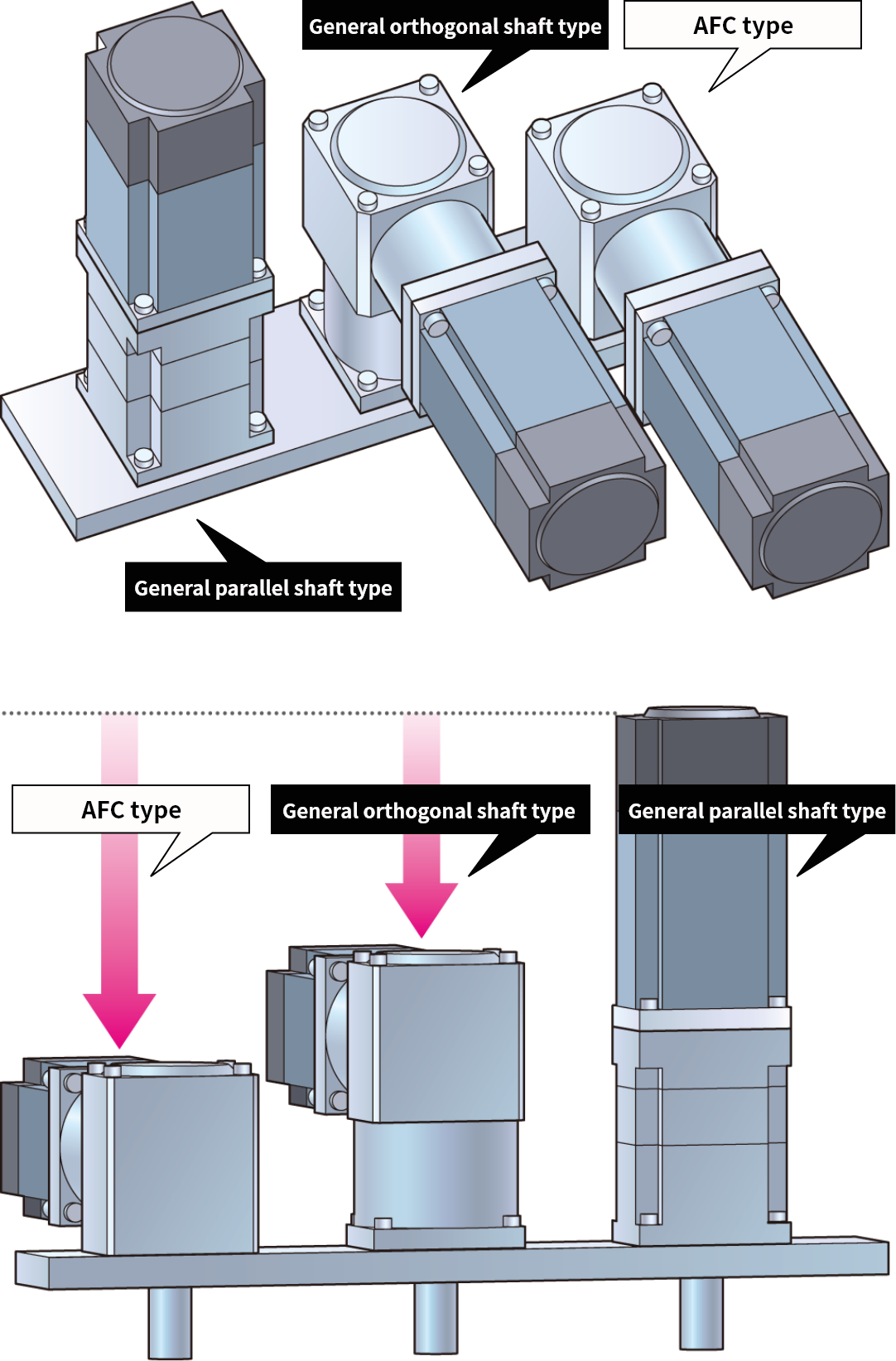

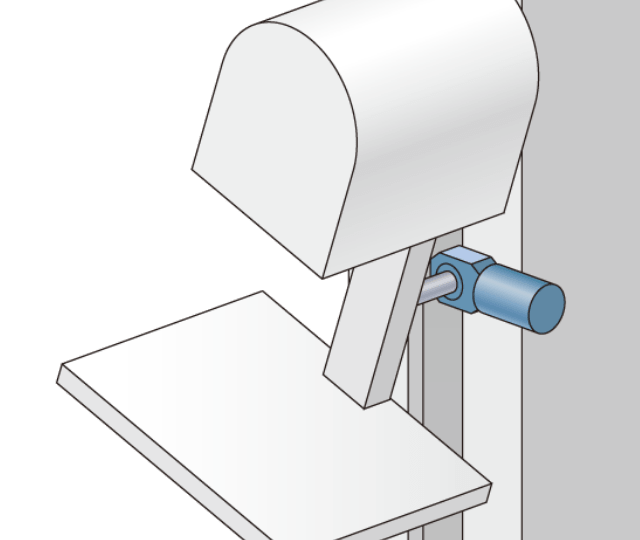

that helps save space

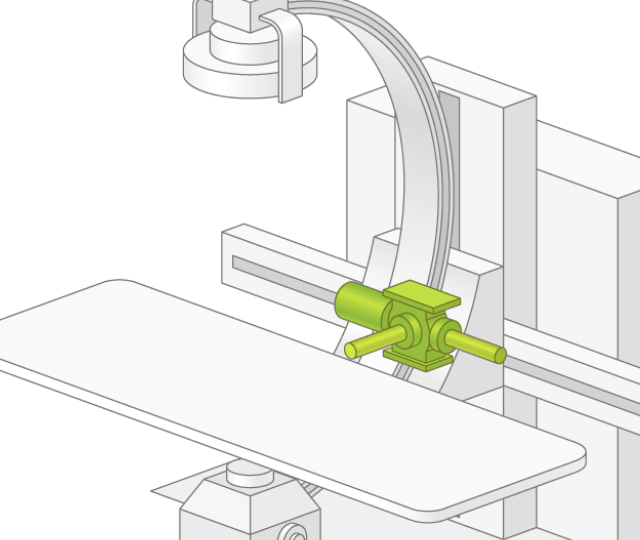

The orthogonal shaft type high precision reducer can be installed to the device at a right angle, preventing the motor from protruding and saving space on the device.

Features

allows smaller designs

It has achieved overwhelming compactness compared to reducers made by other companies.

Selection tool

The selection for high precision reducer for servo motors

proposes the ideal model based on the servo motor type and usage conditions.

Click here if you have decided on the servo motor.

Select the manufacturer and specifications of the servo motor to select the reducer.

Click here to narrow down the specifications of the reducer.

You can narrow down the reducers from the reduction ratio and shaft type.

Click here if you have decided on the device to install the reducer.

You can select the reducer by numerically entering the usage conditions of the device such as speed and mass of the workpiece.

Product line

Motor capacity / 100W to 3000W

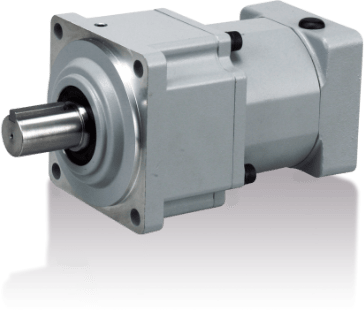

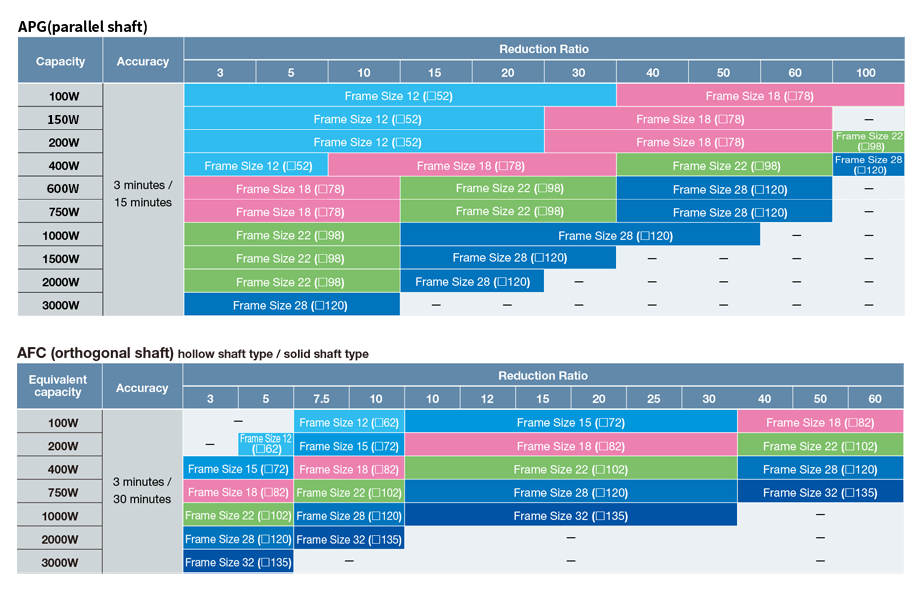

APG parallel shaft / planet type

Reduction ratio / 3 to 100 Backlash accuracy / 3 minutes / 15 minutes

Motor capacity / 100W to 3000W

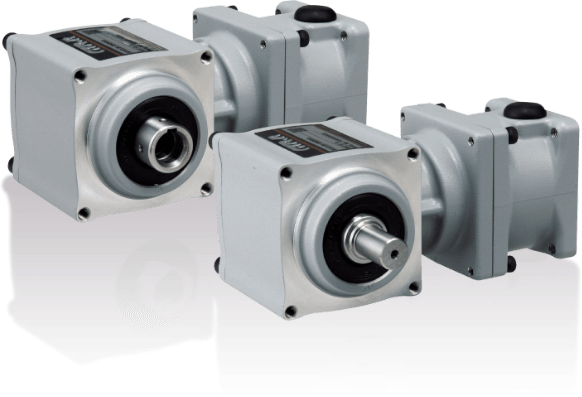

AFC orthogonal shaft / hollow shaft / solid shaft type

Reduction ratio / 3 to 60 Backlash accuracy / 3 minutes / 30 minutes

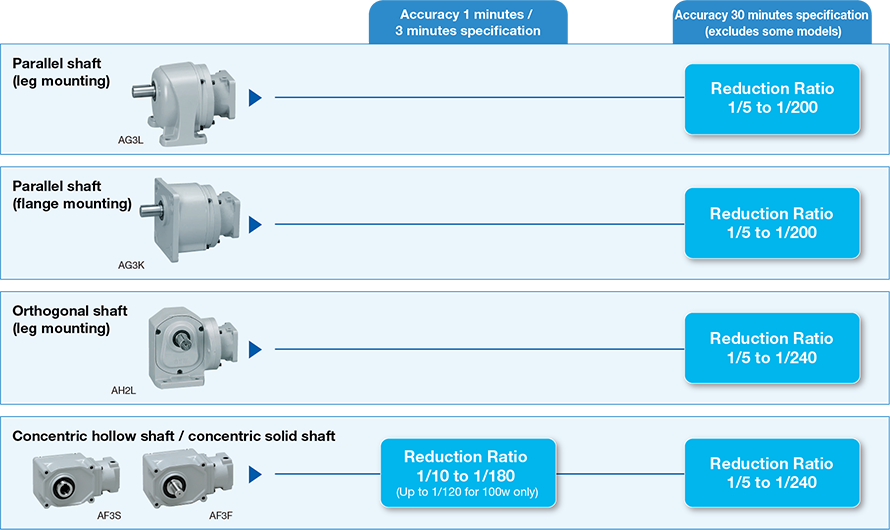

Motor capacity / 100W to 2000W

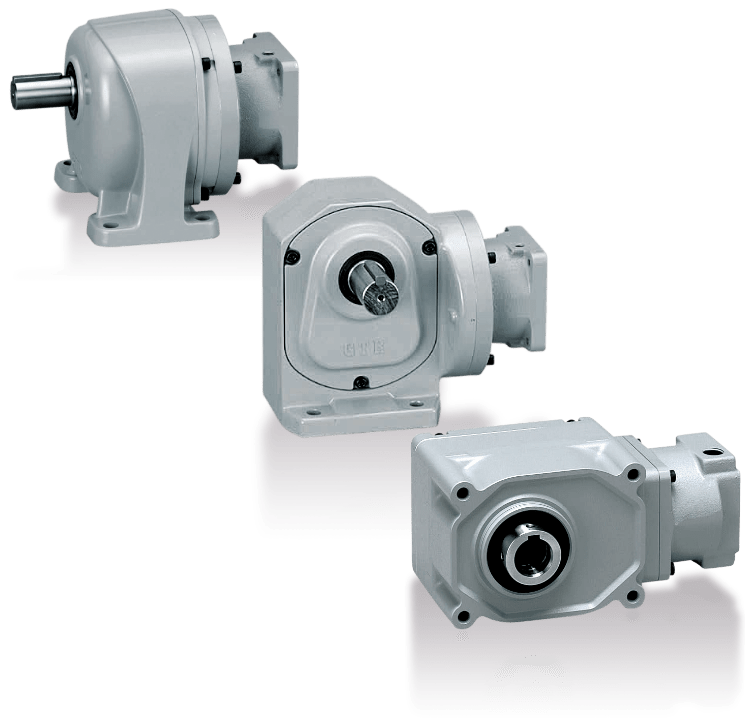

AG3 parallel shaft

Reduction ratio / 5 to 200 Backlash accuracy / 30 minutes

AH2 orthogonal shaft

Reduction ratio / 5 to 240 Backlash accuracy / 30 minutes

AF3 Concentric hollow shaft / concentric solid shaft

Reduction ratio / 10 to 180, 1/5 to 1/240

Backlash accuracy / 1 minute, 3 minutes, 30 minutes

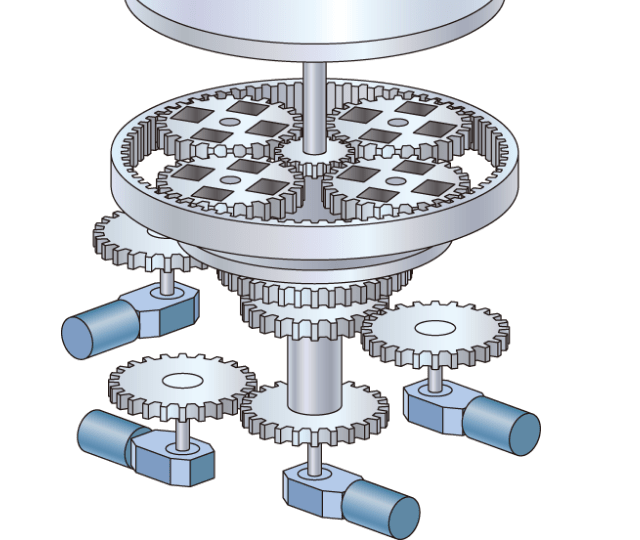

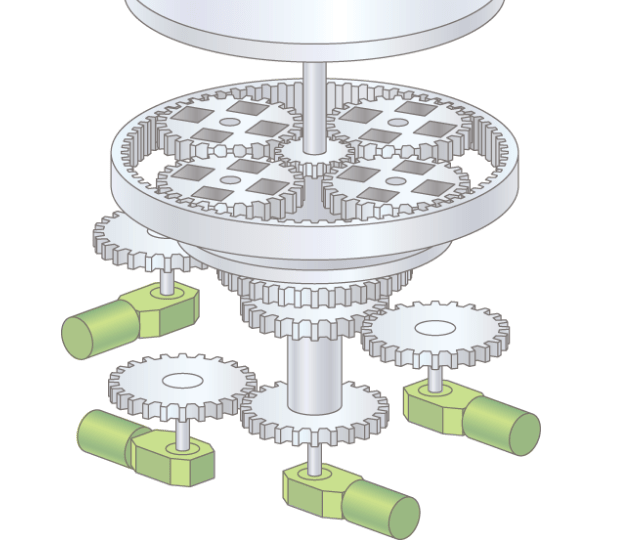

Compact high precision reducer for servo motors

The high precision reducer APG type is compact and highly stiff thanks to the planetary mechanism, which contributes to making the devices smaller.

In addition, the AFC type is made smaller thanks to the specially designed gear case.

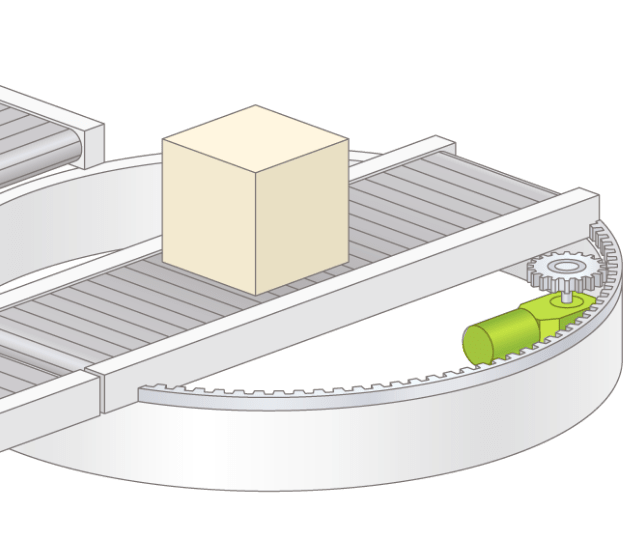

As it can be installed to the device at a right angle, it helps save space on the device.

The gear head has the same shape as the induction gear motor

As the induction gear motor and gear head are common, no extra design changes are needed when changing specifications.

The concentric hollow shaft / concentric center pole shaft (AF3) is available with backlash accuracy of 1 minute and 3 minutes. Provides highly accurate positioning control.

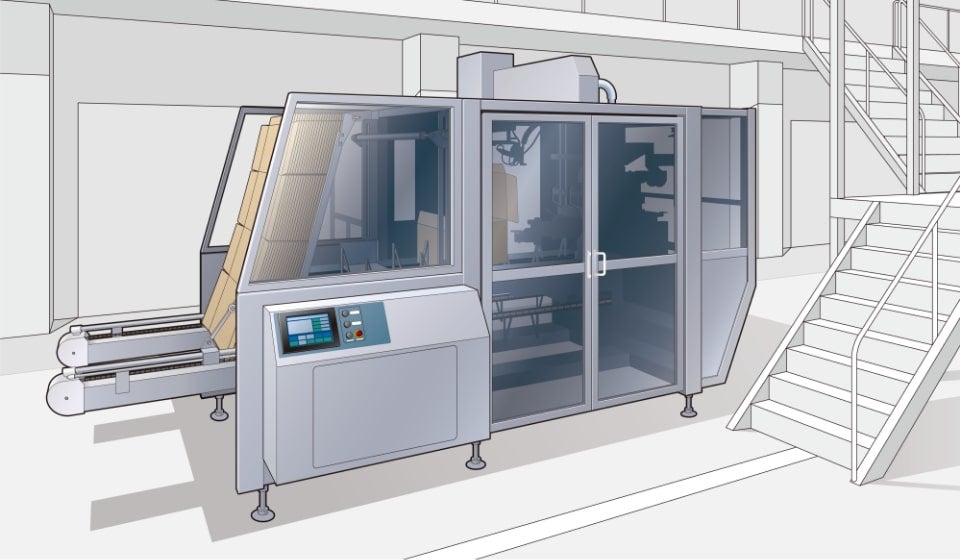

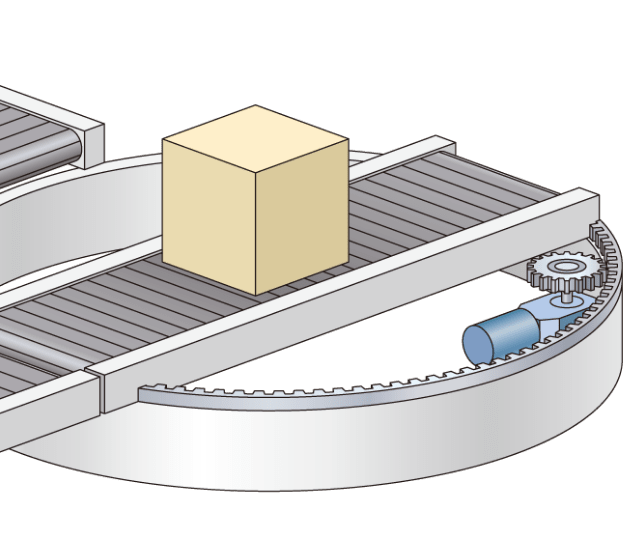

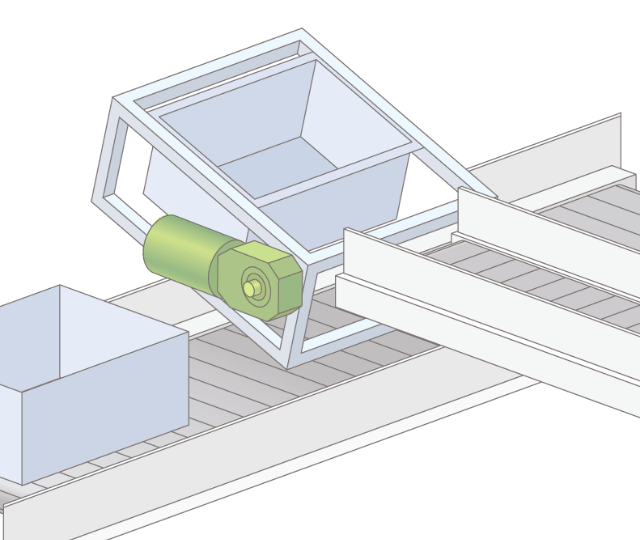

Case Study

"High precision reducer for servo"

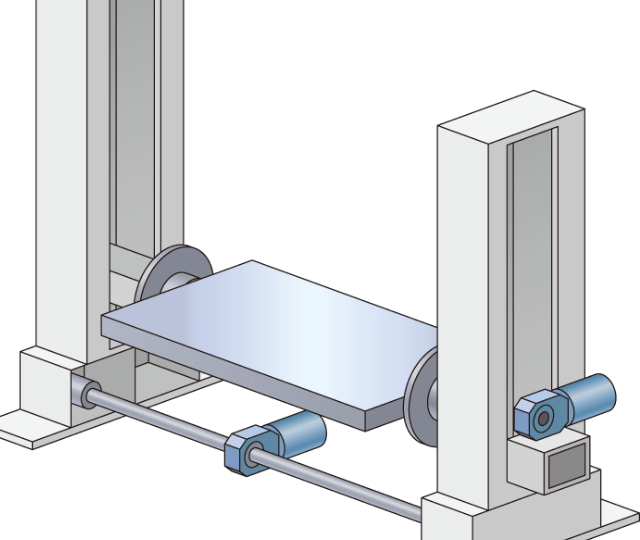

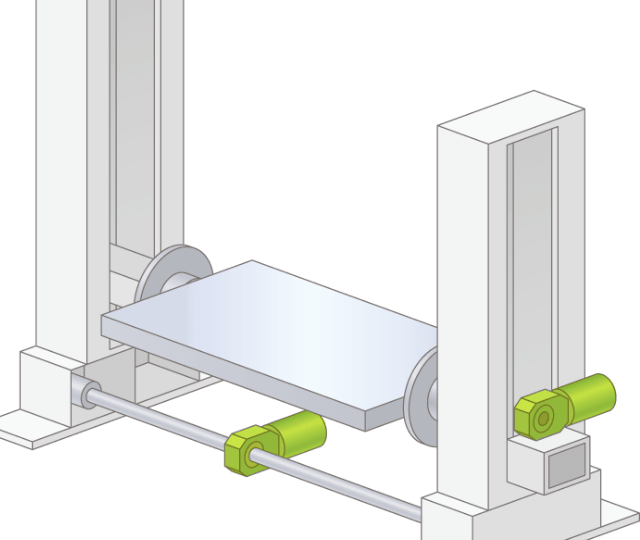

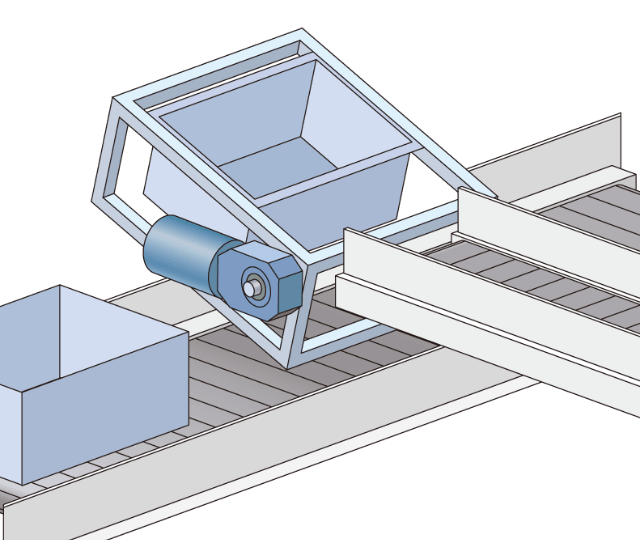

A highly accurate wrap round caser design

The wrap round caser, which supplies and packages accumulated products in cardboards, uses multiple servo motors for each device to perform various processes. As it is necessary to synchronize each process in conjunction with each other, the servo motor needs to be highly functional. The main reduction ratio band used for servo motors is 1/10 to 1/20. However, as some servo motors require low speed and high torque, APG's high reduction ratio models (1/60 to 1/100) were used. As a result, it became possible to control the main motions of multiple servo motors in the device, achieving the ideal design.

Used models

High Precision Reducer for Servo Motors

Operation explanatory drawing

Various processes are performed in a wrap round caser, each of which needs to be linked and synchronized. This requires high-precision motors.

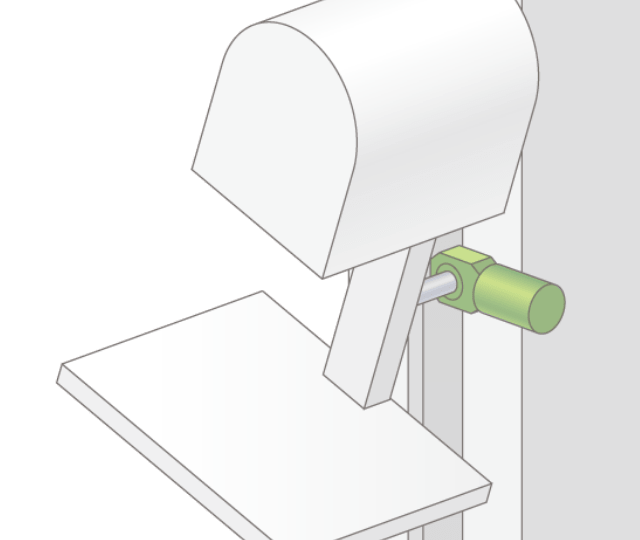

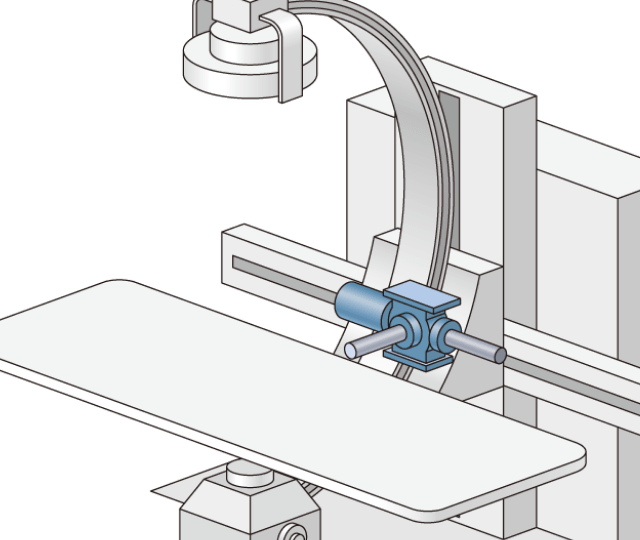

It can be used for various purposes where space-saving installation is required.

Lifting / inverting machine

Medical machine (mammography)

Medical machine (X-ray machine)

Rotary drive machine

Polishing machine

Inverting machine