Virtual Plant Tour

Features of Gear business division

■One of the biggest OEM gear manufacturer which can perform In- House integrated production.

■Integrated production from the design to manufacturing.

■Precision gear plant produces precision gear products for Robotics, Machine Tools, Internal gear products for High precision gear Box and so on.The plant is thermostatic, Lower mist are in control.

■Biggest production capacity among OEM gear manufacturers can perform 500Kpcs/Month.

■Our valued customers are most potential companies in domestic.

Mainly we produce gear products at Anjo HQ plant.

Virtual Plant Tour of Nissei Corporation

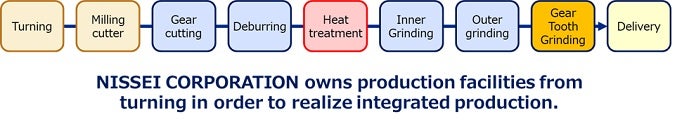

Process until gear completion

Processing engineering

1Turning

2Gear Cutting

3Heat Treatment

4Grinding

➀ Turning

Turning is the method to shape the desired dimension by moving the cutter.

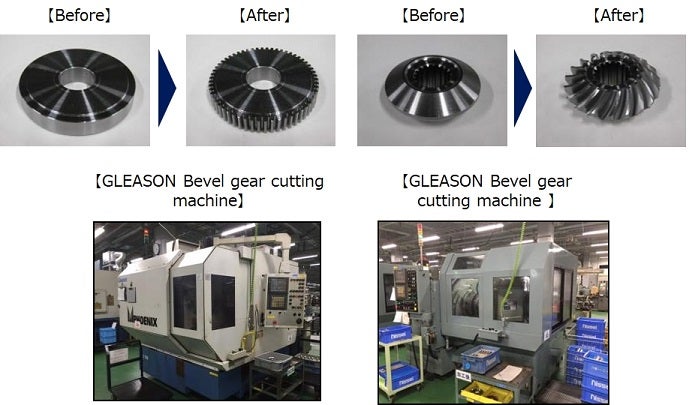

➁ Gear Cutting

Gear cutting machine is the type of machine tool that cut gear teeth and generally, it applies processing with generating gear tooth cutting method.

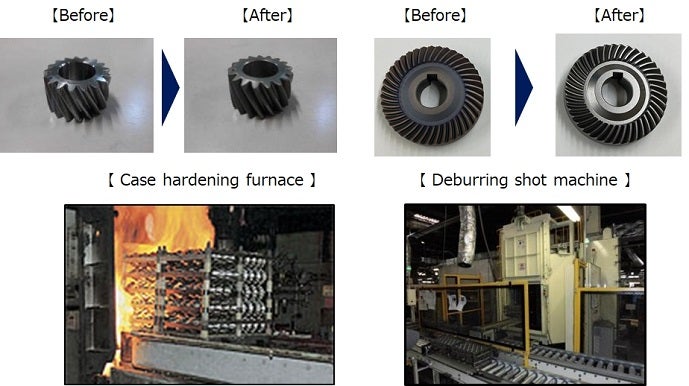

➂ Heat Treatment

Generally, heat treatment is a process of rapid cooling a metal from high temperature state. It hardens the steel and has strength such as wear resistance, tensile strength, fatigue strength. In addition, deburring shot is the process to remove burrs by applying to shot with fine iron balls to workpiece.

➃ Grinding

Generally, heat treatment is a process of rapid cooling a metal from high temperature state. It hardens the steel and has strength such as wear resistance, tensile strength, fatigue strength. In addition, deburring shot is the process to remove burrs by applying to shot with fine iron balls to workpiece.

In-house manufacturing of a spiral bevel cutter

In-house manufacturing of a spiral bevel cutter for about 40 years.

We realized small lots, a wide variety of products, and quick delivery by in-house manufacturing of jigs for each process.

Manufacturing process of gears

link